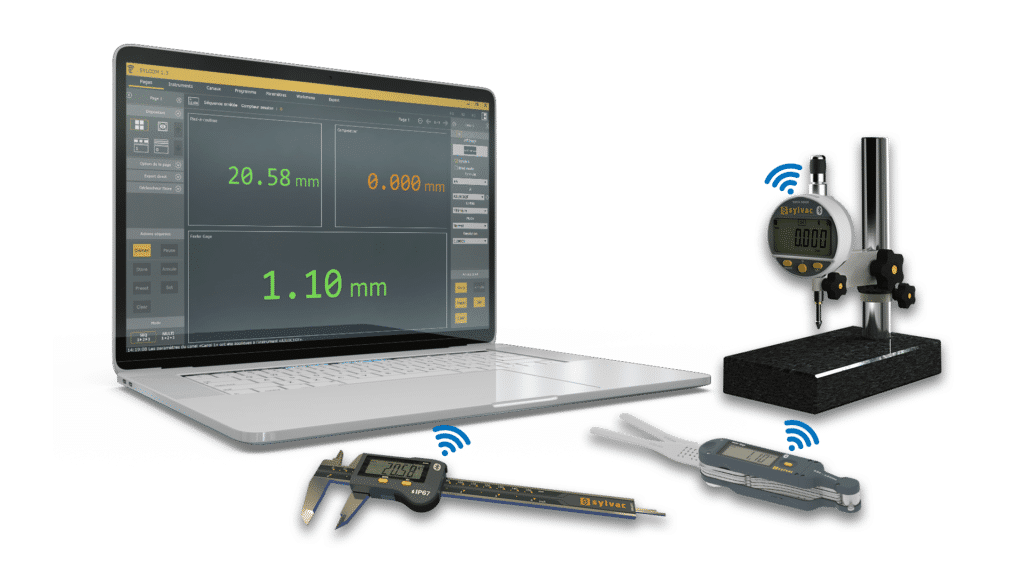

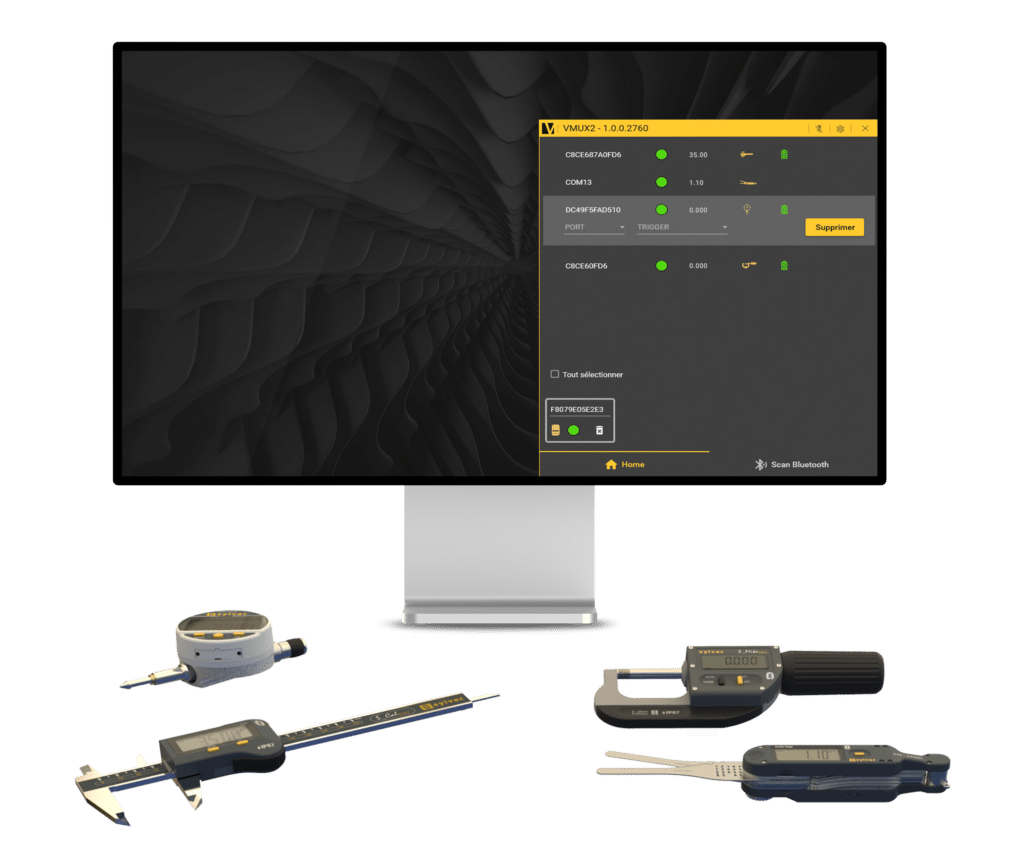

With Sylvac’s advanced Sylcom software, production managers gain an invaluable tool for remote monitoring of live and historical measurement data. This game-changing feature offers real-time visibility into your production processes and provides a wealth of datadriven insights to streamline operations and enhance overall efficiency.

Benefits of Remote Monitoring

Instant Access to Real-Time Data

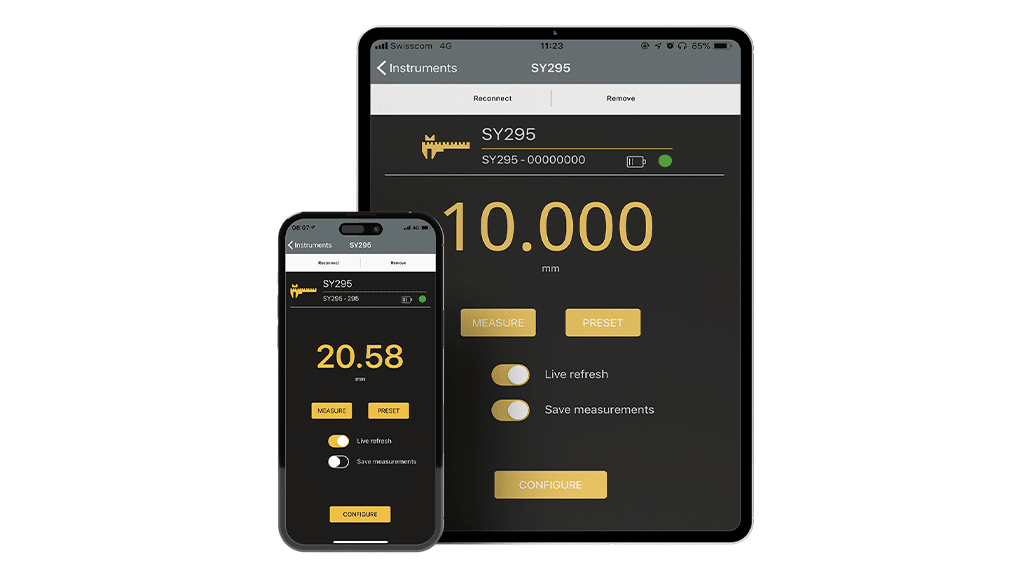

Stay connected to your measurement devices from anywhere in the production facility or beyond. With Sylvac’s remote monitoring, you can access real-time data instantly, enabling you to make critical decisions on the spot and respond promptly to any deviations or issues that arise during production.

Historical Data Analysis

Beyond real-time data, Sylcom also captures and stores historical measurement data. Production managers can analyze trends over time, identify patterns, and gain valuable insights into long-term process performance. This historical analysis allows for better forecasting, smarter resource allocation, and more informed decision-making.

Proactive Issue Detection

Early detection of potential problems is crucial in ensuring smooth production processes. With Sylcom’s remote monitoring capabilities, production managers can set up alerts and notifications for specific parameters. This proactive approach enables swift intervention to prevent quality issues, reducing downtime, and minimizing production disruptions.

Optimize Workflows & Improve Efficiency

Armed with comprehensive data, production managers can optimize workflows, identify bottlenecks, and implement continuous improvement initiatives. Fine-tuning production processes based on realtime and historical data helps maximize efficiency, increase productivity, and reduce waste.

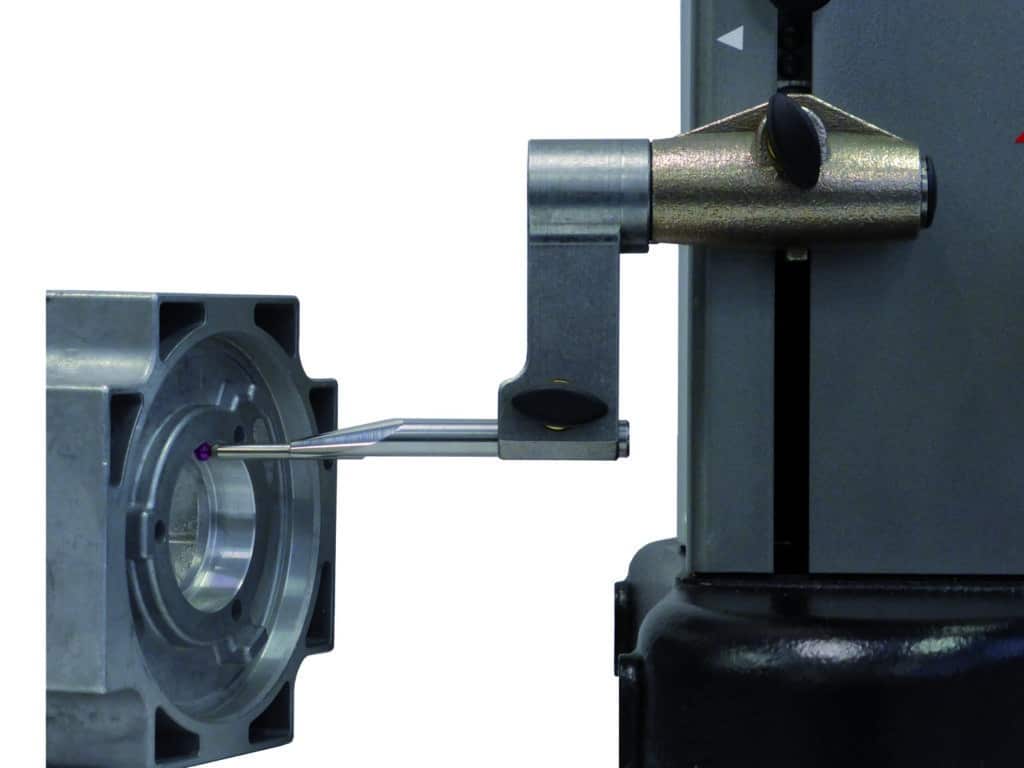

Example Scenario

Imagine a production manager responsible for overseeing a high-precision manufacturing line for automotive components. With Sylvac’s remote monitoring, the production manager can access real-time data from various measuring instruments used in the assembly process. The software allows them to observe critical metrics, such as dimensions, tolerances, and quality checks, in real-time.

During the production run, the production manager notices a sudden spike in rejected parts. Thanks to the immediate access to live data, they quickly identify a calibration issue with one of the measurement devices. They promptly intervene and arrange for calibration preventing further rejected parts and ensuring that the production stays on schedule.

Furthermore, the production manager can use Sylcom’s historical data analysis to review.